New type of subsea basket

Introduction:

Each subsea basket is more than just a steel structure; it represents precision engineering, skilled fabrication, and strict adherence to offshore standards.

Here's a glimpse into the manufacturing process of Sinortek's 3 pcs 4M(13ft) and 2 pcs 3M(10ft) approved and certified subsea baskets, providing a behind-the-scenes look at its creation, from initial design to final shipment.

This is our effort to describe the full journey, from order receipt to delivery.

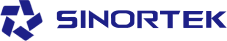

3M Subsea Basket Drawing

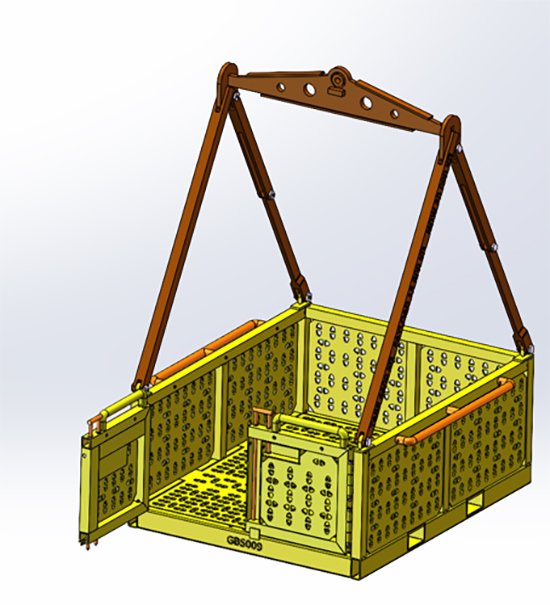

4M Subsea Basket Drawing

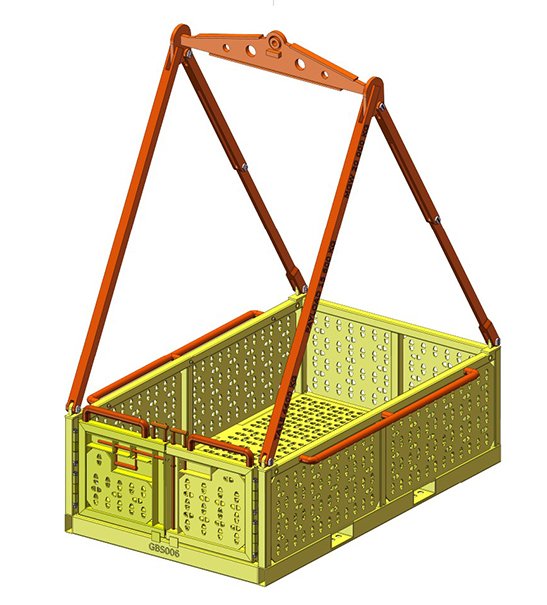

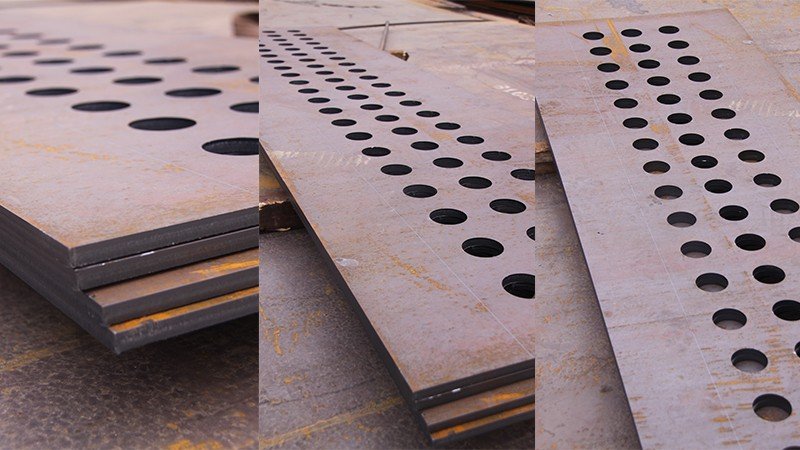

Process 1: Laser Cutting

Programming operation

Thickness of steel 355B: 12 mm/16mm/20mm

Hanslaser cutting machine

Thickness: 30mm max

Machine power: 12,000 watts

Laser Cutting Speed: 1.2 m/min, 0.9m/min, 0.6m/min

Table size: 6000mm by 2500mm

Thickness: 0-30mm

Process 2: Bending forklift channel

Bending the forklift channel

Bending the forklift channel

Process 3: Checking

Check R3

Process 4: Welding

Spot welding the basket

Full welding basket

Welding seam

Process 5: Boom installation and welding

Boom installation

Boom welding

Process 6: Loading Test

3M/4M Subsea Baskets Loading Test.

5pcs finished, and the loading test qualified.

Process 7: Sandblasting

The rust removal grade is Sa2.5

Process 8: Welding Quality Checking

MT Checking

UT Checking

Final process: Production finished

Shipment ready

With the successful completion of five fully assembled and load-tested 4M(13ft) and 3M(10ft) subsea baskets, we've just wrapped up another custom offshore project.

From the initial concept to final delivery, we remain dedicated to providing high-quality solutions that meet the most stringent offshore standards.

Contact us for more information on how we can support your offshore needs.